UArizona Regents Professor Submits Designs to DOD for Three Low-Cost Ventilator Prototypes – One Using a Basketball

Led by Regents Professor Dr. Marvin J. Slepian, a team from the University of Arizona Center for Accelerated Biomedical Innovation has submitted a proposal to the U.S. Department of Defense for three ventilator prototypes – including one using a basketbal

TUCSON, Ariz. – A renowned researcher at the University of Arizona Health Sciences has taken the university’s reputation as a basketball powerhouse to a new level – designing an easily manufactured and low-cost ventilator prototype that uses a basketball to respond to the fast-spreading COVID-19 pandemic.

![Marvin J. Slepian, MD [Photo: University of Arizona]](/sites/default/files/styles/az_very_small/public/slepian_marvin-md_card-wc_2019_inline.jpg.webp?itok=dF7NlnPl)

Marvin J. Slepian, MD [Photo: University of Arizona]

“We are in a period where ventilators are like gold, and the nation anticipates a widespread lack of ventilators to support critical-care requirements across the nation and world,” said Marvin J. Slepian, MD, Regents Professor at the UArizona Health Sciences, director of the UArizona Center for Accelerated Biomedical Innovation (ACABI) and leader of an international team that has submitted three ventilator prototypes for funding by the Department of Defense.

Dr. Slepian’s team submitted a proposal, “PneumEase – Effective Economical Readily Deployable Ventilator Systems,” to the DOD’s Vulcan Challenge, “an open call for innovative capabilities that address the challenges presented by COVID-19, as well as its impacts on public safety and national security processes, systems and resources.”

For the challenge, completed by a public/private partnership including experts at the UArizona along with collaborators at major corporations throughout the world from a range of industries, “we focused on simple designs that work, without advanced bells and whistles,” Dr. Slepian said.

The team was required to submit designs that cost $300 or less, said Dr. Slepian, also professor of medicine, medical imaging, biomedical engineering (associate department head), material sciences and engineering, a member of the UArizona Sarver Heart Center and BIO5 Institute, and a McGuire Scholar in the Eller College of Management.

![Single Foot Pump Ventilator – Constant Pressure [Source: University of Arizona Center for Accelerated Biomedical Innovation]](/sites/default/files/styles/az_very_small/public/basketball-and-foot-pump-ventilators04-inline.jpg.webp?itok=j-GeR_xq)

Single Foot Pump Ventilator – Constant Pressure [Source: University of Arizona Center for Accelerated Biomedical Innovation]

“Today, ventilators largely are designed like Tesla automobiles, fully electronic, computerized with multiple controls, sensors and connectivity,” Dr. Slepian said. “We don’t need such a sophisticated design in light of the urgency created by this pandemic; we need to go back to simple, basic – but extremely effective – designs,” he added.

“To address this challenge, we proposed a system that can provide two modes of ventilation – pressure-supported breaths for patients able to breathe spontaneously; and controlled-pressure ventilation, with set maximum volume, for those unable to breathe spontaneously,” he outlines in the application.

The three designs are: Foot Pump Design – based upon use of an inexpensive, readily available pneumatic foot pump; Sports Ball Design – incorporating commonly available sports balls (U.S. basketballs, footballs, soccer balls); and Printed Piston Design – incorporates a sourced piston cylinder or 3-D printed cylinder design. All designs incorporate humidification, temperature control and filtration of expired air to limit infections and contamination risk. A monitoring-and-control system will be employed for all designs to detect if the patient is breathing spontaneously; not breathing autonomously; or breathing autonomously, but below minimum volumes.

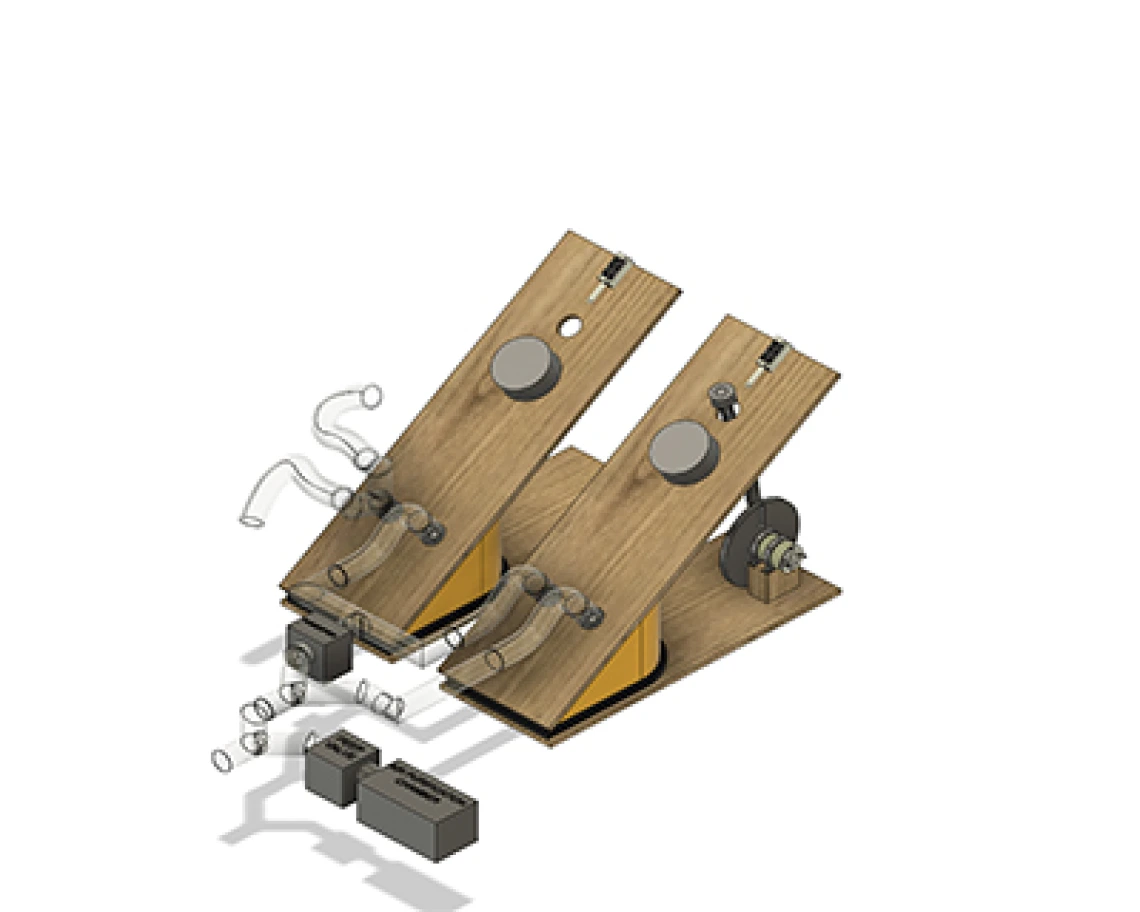

![Double Foot Pump Ventilator – Constant Pressure (left) and Defined Volume, Set Pressure (right) [Source: University of Arizona Center for Accelerated Biomedical Innovation]](/sites/default/files/styles/az_very_small/public/basketball-and-foot-pump-ventilators05-inline.jpg.webp?itok=73q3PQLJ)

Double Foot Pump Ventilator – Constant Pressure (left) and Defined Volume, Set Pressure (right) [Source: University of Arizona Center for Accelerated Biomedical Innovation]

Balls may be equipped with simple plastic connectors, from off-shelf rigid plastic tubing or through a 3-D printed “puncture-and-seal connector,” which allows “instrumenting” the ball with an inlet and outlet as a means to allow attachment of gas-flow tubing. The puncture seal connector allows rapid instrumentation and fabrication of the system by minimally skilled workers, while simultaneously offering secure sealing to ensure prevention of leaks.

Other team members from the UArizona include: David Hahn, PhD, the Craig M. Berge Dean of the UArizona College of Engineering; Monica Kraft, MD, professor and chair the Department of Medicine at the UArizona College of Medicine – Tucson, deputy director of the UArizona Health Sciences Asthma and Airway Disease Research Center and the Robert and Irene Flinn Endowed Professor of Medicine at the UArizona; Christian Bime, MD, MSc, assistant professor of medicine and clinical translational sciences, Division of Pulmonary, Allergy, Critical Care and Sleep Medicine, College of Medicine – Tucson, and medical director, Medical Intensive Care Unit, Banner – University Medical Center Tucson; Sairam Parthasarathy, MD, professor of medicine and chief, Division of Pulmonary, Allergy, Critical Care and Sleep Medicine. Several ACABI members from private industry also assisted in the fast-paced effort.

The UArizona Health Sciences COVID-19 Resources webpage can be found here.

For the latest on the University of Arizona response to the novel coronavirus, visit the university's COVID-19 webpage.

###

NOTE: Photos available upon request.

About the University of Arizona Health Sciences

The University of Arizona Health Sciences is the statewide leader in biomedical research and health professions training. UArizona Health Sciences includes the Colleges of Medicine (Tucson and Phoenix), Nursing, Pharmacy, and the Mel and Enid Zuckerman College of Public Health, with main campus locations in Tucson and the Phoenix Biomedical Campus in downtown Phoenix. From these vantage points, Health Sciences reaches across the state of Arizona, the greater Southwest and around the world to provide next-generation education, research and outreach. A major economic engine, Health Sciences employs nearly 5,000 people, has approximately 4,000 students and 900 faculty members, and garners $200 million in research grants and contracts annually. For more information: uahs.arizona.edu (Follow us: Facebook | Twitter | YouTube | LinkedIn | Instagram).