UArizona Health Sciences Connects Arizona’s Makerspaces in COVID-19 Response

A network formed to support the Health Sciences Design program proves invaluable in uniting the state’s makerspaces.

Tory Middlebrooks, of University Libraries, models a face shield, which is designed to be worn in conjunction with additional PPE such as a mask. Middlebrooks mans the 3D printers that produced the headbands for the face shield.

As initial responses to the COVID-19 pandemic began to unfold, University of Arizona Health Sciences Design Program Director Kasi Kiehlbaugh noticed a trend that was uplifting and concerning at the same time. Across the university, researchers and scientists were mobilizing quickly to find solutions to the critical shortage of equipment needed by health care workers on the front lines, but those efforts were mostly uncoordinated.

Kasi Kiehlbaugh developed the AZ Makers Fighting COVID-19 group to connect people in makerspaces across the state in their efforts to find solutions to the critical shortage of equipment needed by health care workers on the front lines.

“There were multiple efforts across campus in parallel, but nobody was talking to each other,” said Kiehlbaugh. “It became clear pretty quickly that everyone needed to begin moving toward the most optimal designs together instead of working in isolation.”

Most of the efforts revolved around the technology available in makerspaces, collaborative workspaces containing a variety of tools for making, learning, exploring and sharing. Laser cutters, 3D printers, computer numerical control routers and mills, and even sewing machines could potentially be utilized to fabricate much-needed personal protection equipment for medical professionals and parts for the ventilators that keep COVID-19 patients alive.

Tory Middlebrooks, of University Libraries, models a face shield, which is designed to be worn in conjunction with addition PPE such as a mask. Middlebrooks mans the 3D printers that produced the headbands for the face shield.

And when it came to identifying and connecting University of Arizona makerspaces, Kiehlbaugh, who holds a teaching appointment in the College of Engineering, had an edge.

“I had been working to build a university-wide network of people who had these types of spaces so that we could connect the new Health Sciences Design program makerspace into the broader campus community,” she said. “When the coronavirus crisis emerged, I seized the opportunity to leverage the work I had been doing around building a network to mobilize them to do this specific work.”

Kiehlbaugh chose the instant messaging platform Slack as a virtual meeting hub and set up the AZ Makers Fighting COVID-19 group. Using her existing network of campus contacts, she initially invited approximately 50 people from UArizona. The scope soon broadened to include any entity with a community makerspace, including Arizona State University, Northern Arizona University, community colleges and nonprofit community makerspace representatives such as Xerocraft, as well as medical groups such as Carondelet Health Network. Now, more than 110 people are active participants in the AZ Makers group.

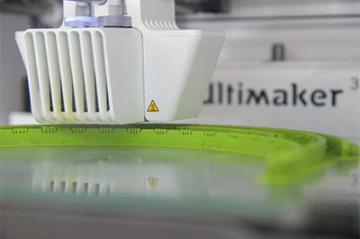

A face shield headband is produced on a 3D printer.

One of the group’s early success stories is supporting a collaboration between Banner – University Medical Center and the Catalyst Studios at University Libraries that has resulted in face shields being produced and delivered to Banner locations in Phoenix. Another team of faculty and staff from the School of Information, the College of Architecture, Planning and Landscape Architecture, and Xerocraft is designing and testing a new face shield design. Several groups are working on mask designs and 3D printing prototypes for testing, while others are developing prototypes for ventilator parts.

“In a very short period of time, we have developed a rapid prototyping and iteration process, and we are bringing in experts to give feedback from the clinical-use perspective,” said Kiehlbaugh, who hopes to gain more involvement from Arizona’s hospital networks, especially rural and critical care hospitals, in the coming days.

These headbands, produced by 3D printers in Tucson, where then shipped to Phoenix to be assembled into face shields and distributed to Banner employees.

“The Health Sciences Design program is a new initiative to develop a program that offers credit-bearing courses for students to come learn the design thinking process in the context of health care challenges. This kind of real-time development of personal protective equipment is a beautiful example of that process in action,” she said. “While I'm not teaching a formal course right now, the process that is being used to facilitate all this is precisely what we will be teaching our students in that program.”