Professor’s teaching philosophy builds confidence with technology, sparks student creativity

Health Sciences Design instructor Matthew Briggs empowers students, including Ruth Salazar, to create projects that transform communities through collaborative innovation.

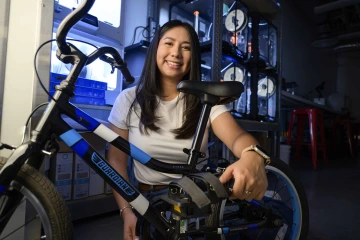

Matthew Briggs encouraged Ruth Salazar to broaden her vision for addressing a health care problem by seeking community feedback, which led her to design an adaptive foot pedal to help children with complex medical conditions ride bicycles.

Photo by Kris Hanning, U of A Health Sciences Office of Communications

When Ruth Salazar enrolled in a University of Arizona Health Sciences course about design thinking, she saw an opportunity to make a difference. The biomedical engineering student and former physical therapist wanted to help people with motor impairments by designing a switch-adapted ceiling fan control.

Salazar designed an adaptive foot pedal for children’s bicycles used at the Children’s Clinics for Rehabilitative Services in Tucson.

Photo by Kris Hanning, U of A Health Sciences Office of Communications

The course instructor, Matthew Briggs, an assistant professor of practice in the Health Sciences Design program and U of A College of Engineering, encouraged her to first solicit feedback directly from a local organization to better shape her project. Following his advice, Salazar connected with Children’s Clinics for Rehabilitative Services, where she previously worked. They proposed a different challenge: create affordable bicycle pedal adapters to help children with complex medical diagnoses keep their feet secure while riding adaptive bicycles.

With Briggs’ encouragement and guidance, Salazar scrapped her initial idea and began developing 3D-printed pedal adapters, refining the design through multiple iterations to meet the clinic’s needs.

Salazar’s story reflects the transformative learning environment fostered by Briggs. His expertise in design and passion for hands-on education empower students to tackle real-world health challenges through innovative design.

“My teaching philosophy has evolved to focus on building students’ confidence with technology through hands-on experience” Briggs said. “I want them to feel ready to run with an idea. My goal is to spark creativity, teach practical skills and build their confidence – not just with the tools, but in themselves, their communities and their careers.”

A journey shaped by making and mentorship

Briggs’ path to his current role in Tucson began at Arizona State University, where he earned degrees in graphic information technology and digital culture.

“I took a 3D modeling class, and they unveiled their new makerspace,” Briggs said. “At that time, they had a ZCorp 3D printer, which is a ceramic printer where you excavate the print. That experience got me really into the idea of the makerspace and being able to build stuff hands on.”

Briggs enters a virtual reality world created by a student as part a Health Sciences Design course.

Photo by Noelle Haro-Gomez, U of A Health Sciences Office of Communications

Hired as one of ASU’s first student employees in the makerspace, Briggs spent his undergraduate years mastering digital fabrication, including CNC milling, a manufacturing process that uses computer-controlled machines and rotating multi-point cutting tools to progressively remove material from a workpiece to produce a custom-designed part. After graduating, Briggs managed the ASU makerspace and co-taught a digital fabrication course, which helped him discover a passion for teaching.

“As a staff member, you’re helping in the shop,” he said, “but as an instructor, you help students conceptually develop and grow.”

To advance his skills, Briggs pursued a Master of Fine Art in Design for Emerging Technologies at the School of the Art Institute of Chicago. There, he managed instructional fabrication shops while blending physical and virtual design. Briggs returned to Arizona during the COVID-19 pandemic and joined Phoenix Forge, the largest makerspace in the Southwest, to oversee its wood and metal shops and instructional development. These experiences prepared Briggs for his role at the U of A Health Sciences.

“I was starting to establish my research at Phoenix Forge, but I didn’t have many opportunities to integrate it,” he said. “Coming here, the ability to fold research into my teaching and makerspace work was really appealing.”

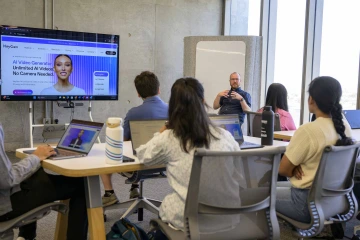

At the University of Arizona Health Sciences, Briggs teaches a range of Health Sciences Design courses, including a core makerspace class for physical fabrication. He also teaches an artificial intelligence and extended reality studio, a virtual design course and a digital audiology class where students develop 3D-printed hearing aid molds.

“I’m focused on inspiring creativity and giving students the applied skills to pursue it further,” Briggs said. “I always do critiques where people show their work – kind of like show and tell for adults. They get feedback from not only me but also their classmates. As a teacher, I have found that peer-to-peer feedback and mentoring is really important.”

Empowering students to create impact

Students in Briggs’ courses progress through a series of three design briefs, assignments that guide them to create solutions for specific problems. Individual projects focus on personal goals and inspirations. Community-focused projects involve collaboration with organizations, such as clinics or nonprofits, to address real-world needs, often yielding tangible outcomes like Salazar’s pedal adapters. Discursive projects spark conversation and explore imaginative ideas that may not yet be practical.

Students in an artificial intelligence and extended reality studio course listen as Briggs introduces an AI video generator software program.

Photo by Kris Hanning, U of A Health Sciences Office of Communications

“We start with something tangible, understanding their own practice,” Briggs said. “Then we build a community of practice, like partnering with a clinic to solve a specific problem. Finally, discursive projects let them explore what’s possible, creating designs that move their field forward by sparking new ideas.”

Salazar’s adaptive pedal project exemplifies the real-world impact of Briggs’ mentorship. After consulting with physical and occupational therapists, Salazar designed large and small 3D-printed pedal adapters to accommodate different age groups.

“I was overdoing it at the beginning,” Salazar said. “Professor Briggs said, ‘You can make this simpler.’ I took his feedback, added elements from other adaptive equipment, and it became a beautiful project.”

The project’s success was evident when the health professionals at the Children’s Clinics for Rehabilitative Services tested the adapters.

“I got a text from one of the therapists, saying that the toddler adapter worked wonderfully for a kid who had never been able to use the bike because the pedals didn’t fit him,” Salazar said. “It was very special, knowing I created something that helped someone enjoy a part of their life they hadn’t before.”

Through his expertise and encouragement, Briggs is shaping a new generation of designers who, like Salazar, are turning ideas into solutions that transform lives.

Experts

Matthew Briggs, MFA

Assistant Professor of Practice, College of Engineering

Assistant Professor of Practice, Health Sciences Design, College of Health Sciences

Contact

Blair Willis

U of A Health Sciences Office of Communications

520-419-2979, bmw23@arizona.edu